Lianyungang Oster Silicon Powder Co., Ltd.

Company Address: 323 Provincial Road Industrial Concentration Zone, Shihu Township, Donghai County, Jiangsu Province

Contact:

Mr. Niu's mobile phone: 13851216155

Phone: 0518-87646666

Email: guangyu668@sohu.com

Fused silica powder

Fused silica powderIt is a powder formed by using high-quality natural quartz and processed through a unique treatment process. Through high temperature treatment, its molecular structure arrangement changes from an orderly arrangement to a disorderly arrangement. Its color is white, with high purity and the following physical properties:

(1) Very low linear expansion coefficient

(2) Good electromagnetic radiation

(3 Stable chemical properties such as chemical corrosion resistance

(4) Reasonable, orderly and controllable particle size distribution. The application range of fused silica powder is very wide, such as electronic packaging, investment casting, high-standard electrical insulation, paint coatings, silicone rubber and other industries. It occupies a pivotal position in optics, aerospace, aerospace, electronics, chemical industry, machinery and today’s rapidly developing IT industry, especially its internal molecular chain structure, crystal shape and lattice change law, which make it have high temperature resistance and thermal expansion coefficient Small size, high insulation, corrosion resistance, piezoelectric effect, resonance effect and its unique optical properties are playing an increasingly important role in many high-tech products.

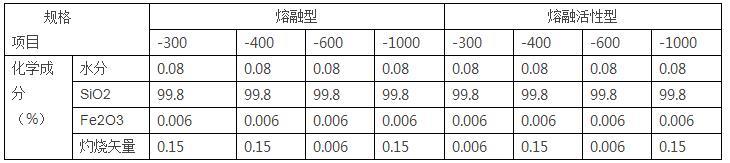

Typical physical and chemical properties are as follows

Application in adhesives and sealants:

Silica powder used in new adhesives and sealants can quickly form a network-like silica structure, inhibit colloid flow, accelerate the curing speed, and greatly improve the bonding and sealing effect.

Applications in the electronics industry:

Silicon micropowder is used in electronic assembly materials, and its main function is to prevent water, dust, harmful gases, slow vibration, prevent external force damage and stabilize circuits. Adding high-purity ultra-fine and nano-silica to more than 70-90% of epoxy plastic packaging electronic materials can make it have excellent processability, small shrinkage, small thermal expansion coefficient, acid and alkali resistance and solvent insulation. Good characteristics.

Application in plastics and modified resins:

Silicon powder is used in plastics, especially in translucent plastic films. The addition of ultrafine silica greatly improves its strength, toughness, waterproof performance, energy storage and heat preservation performance. In plastic structural materials, after adding silicon powder, its mechanical properties can be increased by 1 to 3 times. For modified resin-based composite materials, it can improve the strength, toughness, elongation, wear resistance, smoothness, anti-aging properties of the composite material.

Previous: Soft composite silicon powder

Mobile E-mail:97318091@139.com

Mobile E-mail:97318091@139.com

Address:Donghai County, Lianyungang City TelePhone:13851216155 MobilePhone:13851216155