Lianyungang Oster Silicon Powder Co., Ltd.

Company Address: 323 Provincial Road Industrial Concentration Zone, Shihu Township, Donghai County, Jiangsu Province

Contact:

Mr. Niu's mobile phone: 13851216155

Phone: 0518-87646666

Email: guangyu668@sohu.com

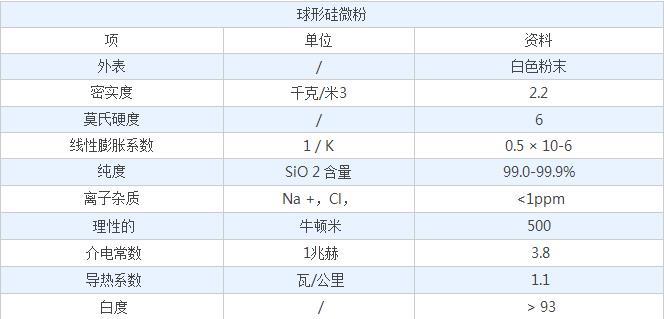

Spherical silica powder

1. Basic instructions

Spherical silica powder is made of selected irregularly-angled silica powder as a raw material, and processed into a spherical shape by flame melting method to obtain a spherical silica powder material with small specific surface area, good fluidity and low stress. Lianyungang Oster Silicon Powder Co., Ltd. is a professional silicon powder manufacturer.

Why spheroidize?

The surface of the ball has good fluidity and is evenly mixed with the resin to form a film. The amount of resin added is small and the fluidity is very good. The filling amount of powder can reach high, and the weight ratio can reach 90.5%. Therefore, spheroidization means filling of silicon powder With the increase of the rate, the higher the filling rate of the silicon powder, the smaller the thermal expansion coefficient and the lower the thermal conductivity, and the closer the thermal expansion coefficient of monocrystalline silicon is. The better the performance of electronic components produced therefrom.

Secondly, the stress concentration of the spheroidized molding compound is very small and the strength is very high. When the stress concentration of the angular powder molding compound is 1, the stress of the spherical powder is only 0.6. Therefore, when the spherical powder molding compound encapsulates the integrated circuit chip, The yield is high, and it is not easy to cause mechanical damage during transportation, installation and use.

Third, the spherical powder has a small friction coefficient and less wear on the mold, which makes the mold have a long service life. Compared with the angular powder, the service life of the mold can be doubled. The packaging mold of the plastic compound is expensive, and some Imports are also needed, which is also important for packaging factories to reduce costs and improve economic efficiency.

2. Detailed parameters

3. Research on spherical silica powder

Large-scale integrated circuits have higher and higher requirements for packaging materials, not only requiring ultra-fineness and high purity, but also requiring low radioactive element content, especially for the shape of the particles. High-purity ultra-fine fused spherical silica powder (referred to as spherical silica powder) has high dielectric and high heat resistance. High filling volume, low expansion, low stress, low impurity, low friction coefficient and other superior properties have become indispensable high-quality materials in the substrate and packaging materials of large-scale and very large-scale integrated circuits. The production technology of high-purity spherical silica powder has been patented abroad in the early 1980s. In the early 1990s, my country began to introduce spherical silica powder. Currently, Japan and the United States can produce materials, and Germany and Russia also master this production technology. The preparation of spherical silicon powder in foreign countries usually adopts high-temperature silicon dioxide fusion spraying method, gas flame method and the hydrolysis method of controlling orthosilicate ethanol and silicon tetrachloride in the liquid phase. Monodispersion methods can also be used to prepare sub-micron spherical particles. Silica powder; can also be made into hollow spherical powder with adjustable wall thickness and particle size by special process. The process is complex, these methods are still in the laboratory stage in China, and there are greater technical difficulties. This is one of the important reasons why high-quality spherical silica powder cannot be produced in China.

Previous: Ultra high purity quartz sand

Mobile E-mail:97318091@139.com

Mobile E-mail:97318091@139.com

Address:Donghai County, Lianyungang City TelePhone:13851216155 MobilePhone:13851216155